Workshop: DIY 3D printer WS2012

A Workshop w7th day, 13th November 2012

Today is the last day of the workshop. Unfortunately, not all problems are solved yet. Two teams have problems with their heating injectors. Due to the high temperatures needed to manufacture ABS, also the electronics are causing problems. They decide to change the material and work with PLA instead, because the processing temperature is much lower. The defect heating injectors were repaired and necessary spares used.

After pleasing progress, all teams have now printed something with their printer, the circuit board of one group has burnt through. The team identifies the mistake and bridges the defect. We can move on.

The final summary of all participants is very positive. They all praise the steep learning curve in various disciplines. The occurring problems were a bit daunting but could always be solved or avoided. All participants would wish to spend more time printing with their 3D printer. We discuss whether the great part of independent learning and working should be reduced. Then, the construction kits would contain instructions or previously installed components. By that, we could gain more time to print. The majority says that the course contents shouldn’t be changed but the length of the workshop should be 10 days in the future.

6th day, 12th November 2012

Although it seems like some problems disappeared over the weekend, we are not really moving forward. One big problem is the temperature. The stepping motors are getting so hot that the electronics are shutting off and the heating rack is not receiving the necessary operating temperature. One stepping motor is even breaking down. The teams live the stress of creators, but still solve the problems fast: one team adds a heat sink, one team uses the robust power supply as cooling fan and the others use an old graphic card fan from a computer to solve the problem. And it works!

But now we have problems with the heating injectors. Realistic problems, maybe too realistic ;-)

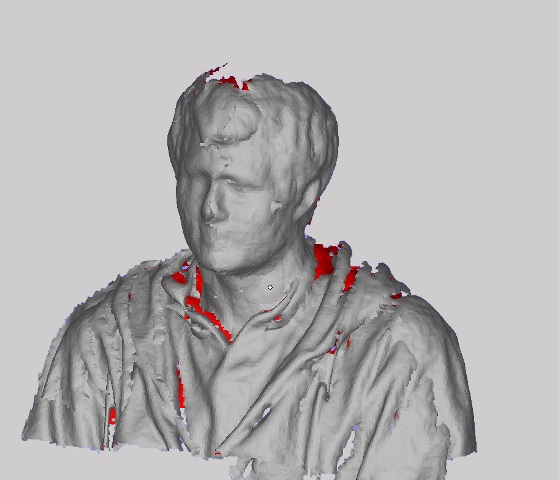

A digression into 3D scanning offers some variety. As a possible prospect for future IDW workshops, the teams are looking at two interesting 3D scanners.

In the afternoon, the teams present their work. During the whole course, we can see how great the students work together. You can also see it while watching the presentations: the teams coordinate with each other; every team talks about another aspect of the common problems. Although we hear three presentations about the construction of a 3D printer, they are all different and very interesting.

5th day, 9th November 2012

Friday at 16.45 o clock, the students leave involuntarily :-)

Technically, I don’t have to write any more.

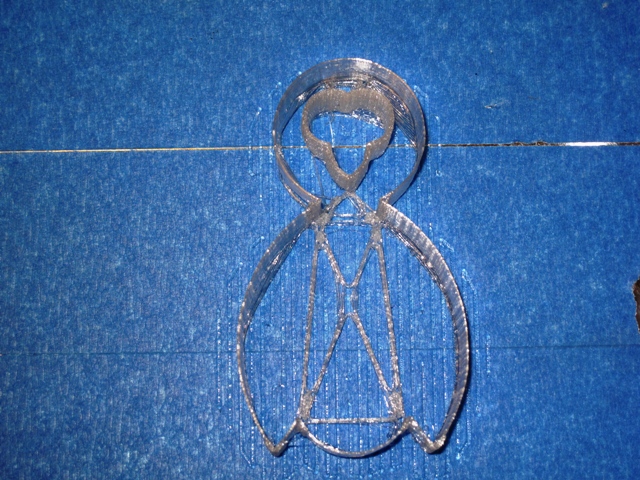

The day is determined by the wish to print the first component with the printer until the evening. There are always small problems. The solder is melting through the high temperatures on the hot end, a thermistor is broken. One group is nearly finished until a stepping motor shuts down. The others are also getting extremely hot. The team goes into the weekend disappointed. It looked good at first but then so many problems occurred. AND not even one solution before the weekend started. But that is the practice of technical projects.

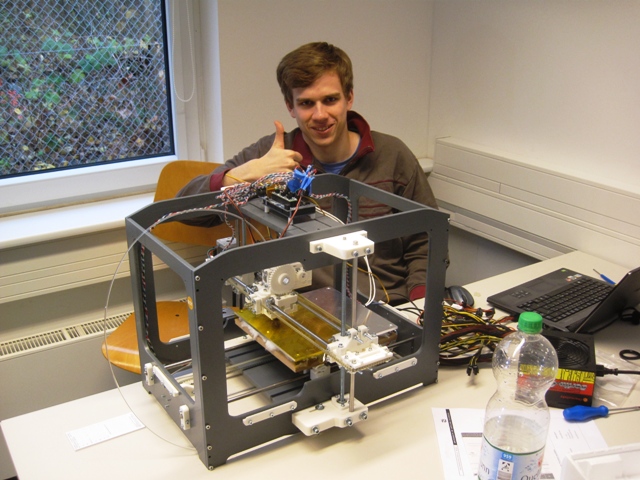

One group is confident, the printer is working perfectly. The first prints don’t look that good, but that will be fixed on Monday with the fine tuning of the parameters.

Now starts the weekend end the relaxing.

It works!!

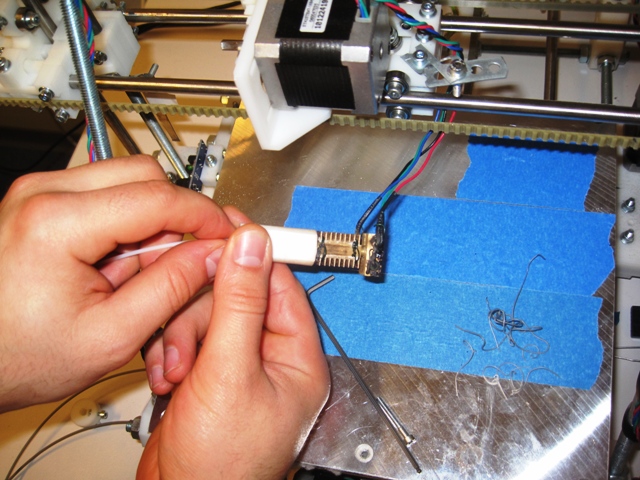

Hot End

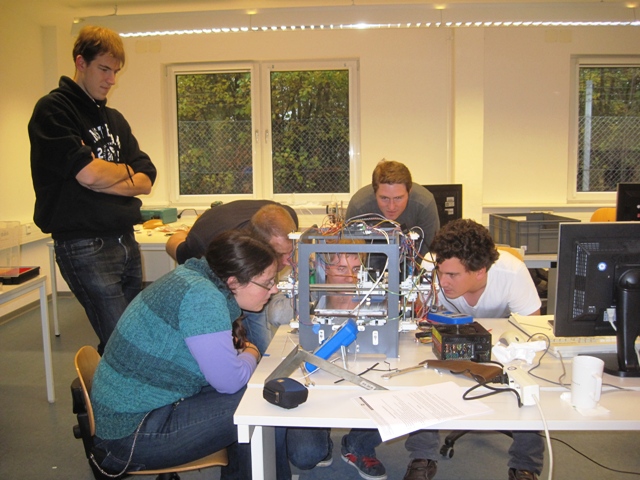

Concentration

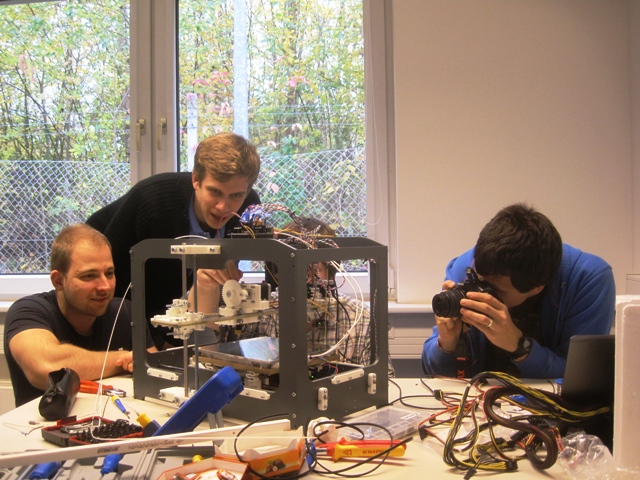

It works!!!

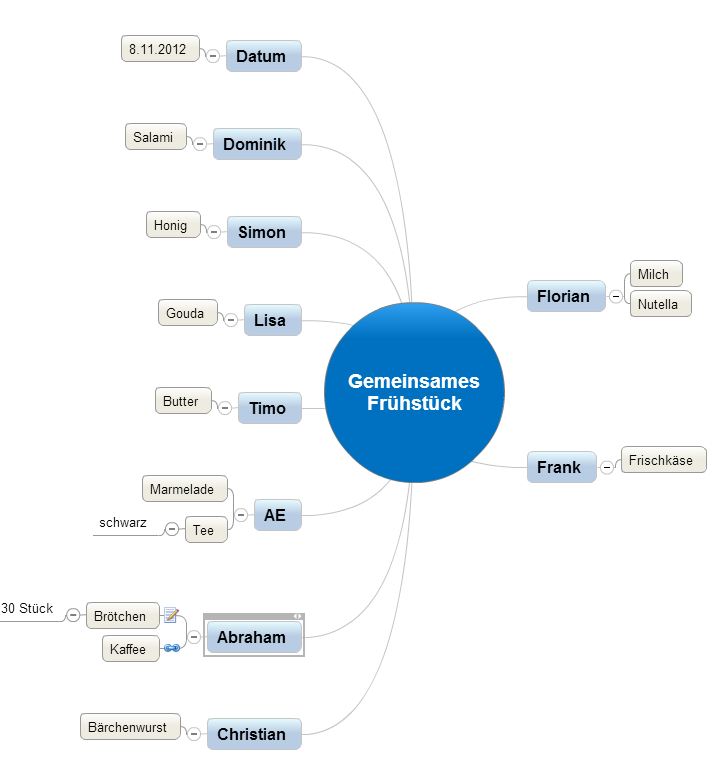

4th day, 8th November 2012

The project planning was successful, and the joint breakfast was a success as well.

The briefing is carried out by the whole group. All teams are on a comparable project state.

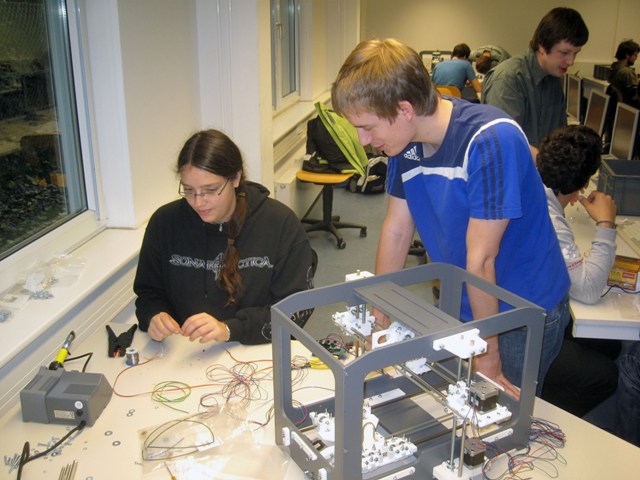

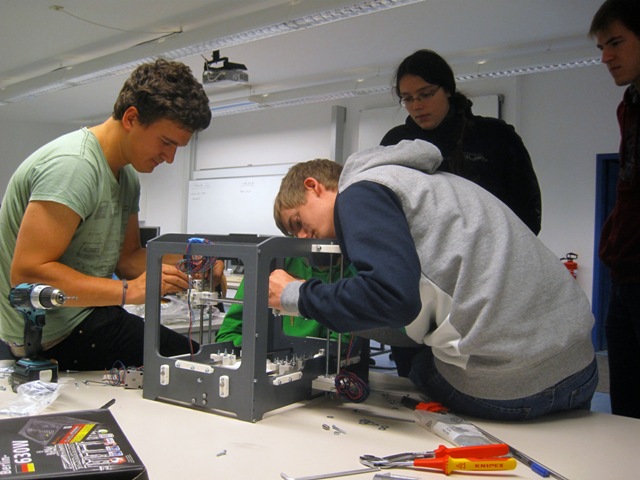

With new energy the teams get to work. Today, we want to install the last mechanical components, wire the technical components and test everything.

All teams have problems with the end stops. Unfortunately, a note about the necessary bridge is missing on the circuit boards. This problem costs time and nerves but the satisfaction is much greater after finding and removing the mistake.

3rd day, 7th November 2012

We are taking a step forward. The teams are working fast. Teamwork is successful, also between the different teams. If someone has a problem, members of the other teams stop their work and start helping.

One student brings his own 3D printer with him. Immediately everyone is comparing, evaluating and discussing. It seems like some are already planning to buy their own construction kits to build a 3D printer at home.

Interdisciplinarity is the focus. Everyone is bringing in his/her own ideas and we find solutions for all problems. Internet research shows us interesting pages and demonstrates how current the topic is and how big the international community of RepRaper is.

In the evening, we start the laser sintering machine to create missing construction parts. All teams have installed the mechanical components of the printer and already started with the first cabling. The control bord is complete. Tomorrow we will test the first components.

And don’t forget the joint breakfast!!

2nd day, 6th November 2012

Wow, how fast!

The group size of 3-4 students seems perfect.

We are working fast. Especially the frame for the FH printer constructed by Christian is easing our work and we can save time. Hopefully, this will continue.

We screw, file, argue/ reconcile (no, just controverse discussions ;-), and the teams make progress, everyone is learning.

"Some parts don’t fit, okay then let’s change the data in CAD and print new fitting components. Wow, we are already using 3D printing."

A new challenge: the threaded rods for the Z axis must be customised with the lathe. Also in this new task, the students learn to handle the lathe and manufacture the needed Z axes.

Unfortunately, one member of the course is sick, everybody wishes a fast recovery.

That’s the thing!!!

Group work

How to twist

Get well soon!

1st day, 5th November 2012

Interdisciplinary, but for real.

Only Agriculture is missing.

One seat is still available. Anybody interested?

Hard to believe but out of 6 faculties, 5 are represented.

Represented by:

Marcus, Faculty of Social Work and Health

Dominik, Faculty of Computer Science and Electrical Engineering

Daniel, Faculty of Computer Science and Electrical Engineering

Frank, Faculty of Mechanical Engineering

Florian, Faculty of Mechanical Engineering

Mirko, Faculty of Computer Science and Electrical Engineering

Lisa, Faculty of Computer Science and Electrical Engineering

Simon, Faculty of Business Management

Anne-Elisabeth, Faculty of Media

Timo, Faculty of Computer Science and Electrical Engineering

Sascha, Faculty of Computer Science and Electrical Engineering

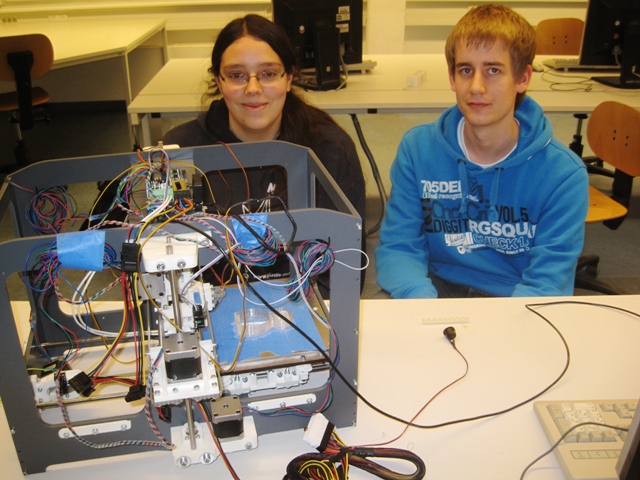

According to the indicated division, we built three work teams and each will build its own 3D printer. The teams will of course also cooperate with each other.

After the mandatory introduction, we visited the opening event of the 7th IDW. We had coffee, tea, buns, cake and a nice dialogue with other members of the university that are active in the interdisciplinary week. After that, we finally started and the teams began their work.

Prologue

....

The prototype is working.

....

The necessary connection components, extruder components and axe abutments are ready with the help of generative production processes. Christian picked up the nuts, threaded rots and profiles. The bearings arrived.

The tooth belts are here. Now we only have to mill the housing plates. The electronics is already there. Only the heating plates are missing. But it will work.

....

It worked. The heating plates arrived and the housings are ready.

....